Technology Blog

What Every Extra Minute of Spindle Activity Means For Your Bottom Line

How many machine shops spend 10 to 20 minutes a day per CNC machine, distracted by coolant tending at the start, end or during a shift? What if these shops could totally eliminate this wasted time and run their spindles more?

One of the upsides to automatic coolant refill machines like our FullShop™ Automated Coolant Delivery System is the ability to top-off CNC machines with the correct concentration—no manpower required. When workers are freed up and a machine has the correct coolant concentration, it’s more likely to run at its maximum rate for more hours of the day. And every extra minute the spindles are spinning puts money back in your pocket.

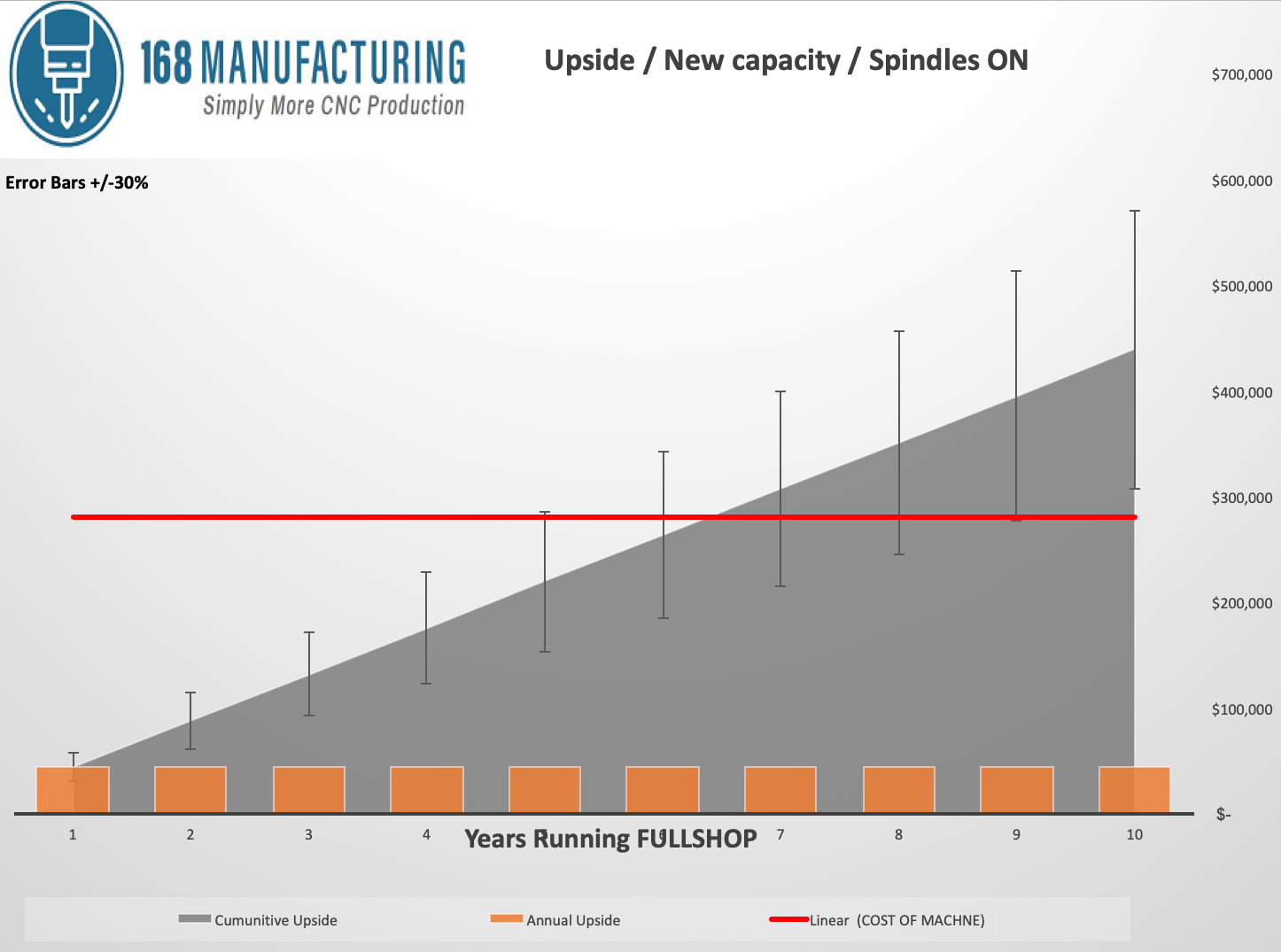

Let’s break down what these productivity gains mean for your return on investment (ROI).

Every Minute Counts

FullShop™ automatically provides each machine with an individualized top-off ratio that is optimized for a specific machining process, keeping the spindles spinning at their maximum rate. This capability leads to incremental gains in productivity that begin to pay off after just one week of operation. And when you extrapolate these values over weeks, months and years, the additional profit is substantial.

As an example, let’s look at a machine shop with 100 CNC machines that runs 17 shifts per week—a first, second and third shift from Monday to Friday, and two additional shifts over the course of the weekend. At an outbound dollar rate of $100 per hour and a 30-percent profit rate, the shop will experience the following financial gains with only one extra minute of spindle activity per shift:

- $850 of new profit per week

- $3,655 of new profit per month

- $43,860 of new profit per year

Based on these productivity gains alone, the machine shop will easily make back its money on a FullShop™ machine after only a few years.

Learn More

We have only a few blog posts left to cover in our series about ROI. Make sure you stay up-to-date on the latest news by visiting [www.168mfg.com. You can also learn more about FullShop™ by downloading our data sheet.