The FullShop™ App

Monitor So You Can Manage

In addition to our FullShop™ system, we offer a hardware-free solution to help you take control of coolant management. The FullShop™ cloud-based app enables both CNC machine shop operators to get a handle on their coolant management practices — and coolant distributors to better serve their CNC customers.

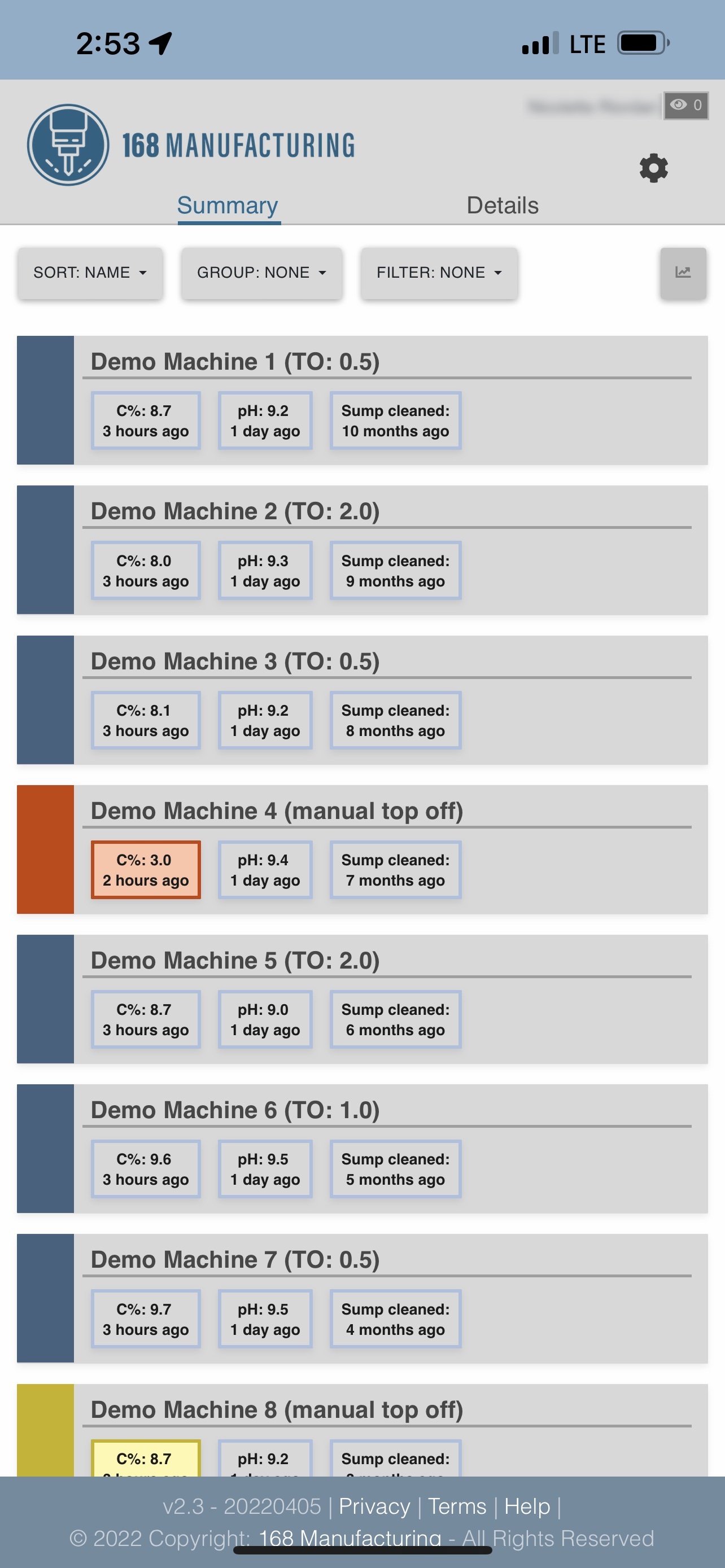

It tracks key coolant parameters in machine tool sumps, providing actionable insights into coolant trends and empowering users to better manage and optimize machine health. It also delivers the data as user-friendly visualizations that are accessible from smart devices and web browsers.

Features

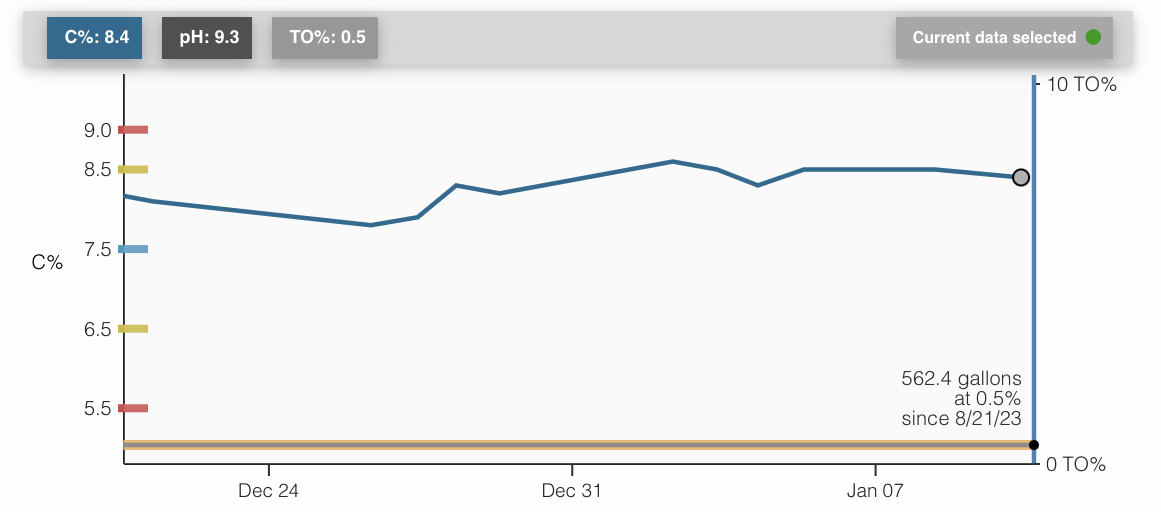

Data Visualizations and Digital History

FullShop™ simplifies the collection of coolant parameters for trending sump concentration, pH levels and more. It displays data and trends in a sleek, easy-to-ready way and offers a time-stamped audit trail of historical events.

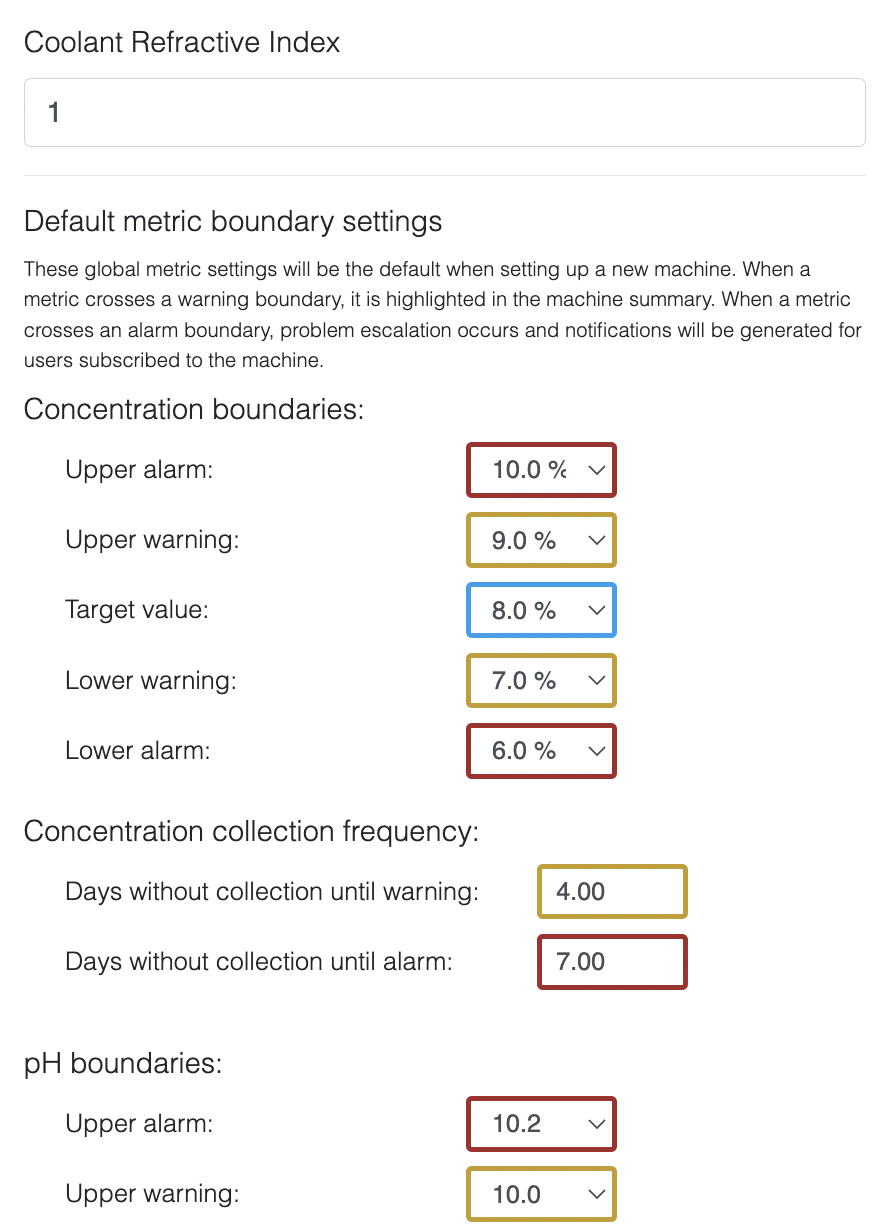

Notifications and Auto-reporting

FullShop™ alerts machine subscribers if coolant parameters have crossed their predefined limits. It also has notifications for events like sump cleaning, as well as weekly email reports to stakeholders with a helpful summary of the entire shop.

Best Practices

FullShop™ is built for driving best practices for coolant management. You will know when people are not doing the work, keeping your team accountable. It will also help you achieve predictable sumps, resulting in increased shop profitability.

How It Works

- Configure. The first step is to set up your shop — a process that takes only 2-3 minutes per CNC machine.

- Collect. Next, start tracking and visualizing coolant parameters like sump concentration, pH balance and cleaning events — no matter where you are.

- Collaborate to Optimize. Finally, review and act upon trends with other stakeholders through the app’s notification and messaging capabilities.

Benefits and Advantages

Greater Accountability — No Spreadsheets Required

The FullShop™ app drives success and continuous improvement for the collection of key coolant data, offering a truly paperless coolant management solution and keeping coolant programs from going off the rails.

By aggregating all the data in one place, it also helps you continuously improve refractometer readings, transforming ad-hoc processes into a regular routine that is actionable, accountable and easy to use.

More Optimal Coolant Usage

Empowered with real-time coolant data and historical trends, FullShop™ enables you to optimize the way your CNC machines use coolant. As a result, you can expect to:

- Improve your ROI.

- Reduce tooling wear and costs.

- Free up skilled CNC machinists and maximize labor.

- Reduce machine stoppages due to low or flooded CNC coolant.

- Have the confidence everything is working as it should — even overnight — eliminating unplanned downtime and maintenance.

How to FullShop ™

Learn how to get up and running quickly with the 168 Manufacturing Coolant Health app, which lets you easily track key parameters in your CNC machine tool sumps. In the following videos, our experts walk you through the simple configuration process and provide a helpful overview of the app's many features and functionalities, including data entry, visual notifications, machine sorting and more. You'll also learn how the app displays data and trends over time.