Technology Blog

Less Tooling Costs Means Tens of Thousands of Dollars Back in Your Pocket

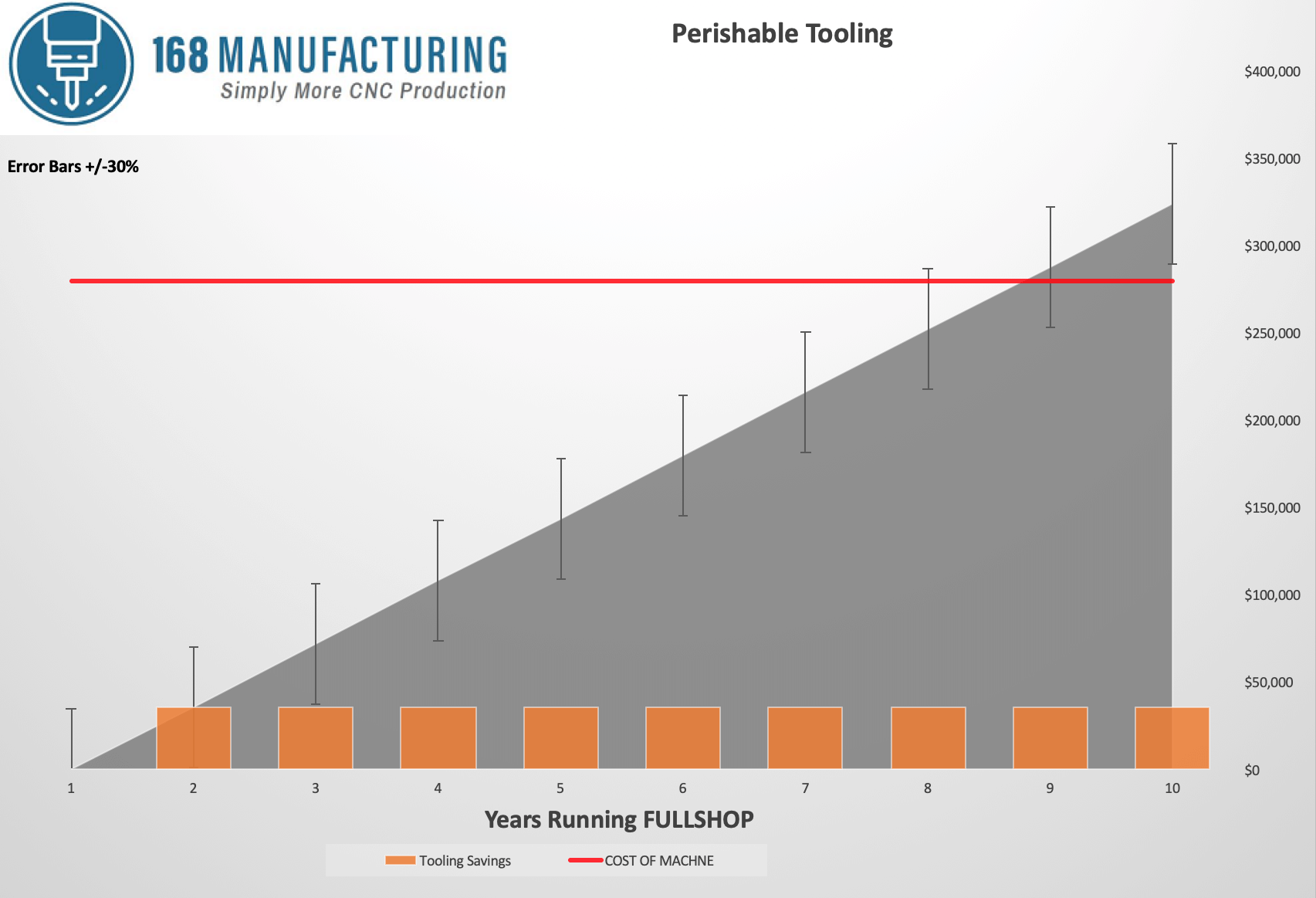

When evaluating the performance of an automatic coolant refill system, one of your first questions is probably about your return on investment (ROI). If you’re like many shop owners or operations managers, it’s tempting to consider ROI only in terms of labor costs. But while labor does contribute to your ROI, it doesn’t tell the whole story—especially where coolant is concerned.

The reality is coolant automation can help you maximize ROI beyond just labor costs alone. One of these other areas is tool wear.

Predictable Concentrations = Less Tool Wear, More Savings

Automatic coolant refill systems like our FullShop™ Automated Coolant Delivery System not only deliver makeup coolant to CNC machines, but they also deliver predictable in-sump concentrations. We accomplish this by individualizing each CNC machine’s makeup percentages according to an optimal setting, which we optimize using a basic trend line.

Thanks to this long-term predictability, your preferred brand of coolant runs optimally and delivers on the promise of extended tool life. And when your tools don't wear as quickly, you buy fewer of them over the course of a year. It’s as simple as that.

How would a 5- to 10-percent decrease in tooling cost affect your bottom line? What about 25 percent? For shops that cut exotic material, these savings can be dramatic. While your use case is unique, we find that a high percentage of our users benefit from having more predictable coolant concentrations. Many shops in our demographic spend $100,000 or more a month on tooling, so these cost savings really do add up.

Over the next few weeks, be on the lookout for more blog posts that will explore other ways FullShop™ can help you achieve true ROI. In the meantime, you can learn more about this game-changing system in our data sheet.