Technology Blog

How FullShop’s Real-Time IoT Feature Saved Us Hundreds of Dollars—and a Big Mess

At Precision Tool Tech, we eat our own dog food. As one of the first users of the 168 Manufacturing FullShop™ Automated Coolant Delivery System, we recently had an incident that demonstrates the power of this system’s real-time Internet of Things (IoT) capabilities.

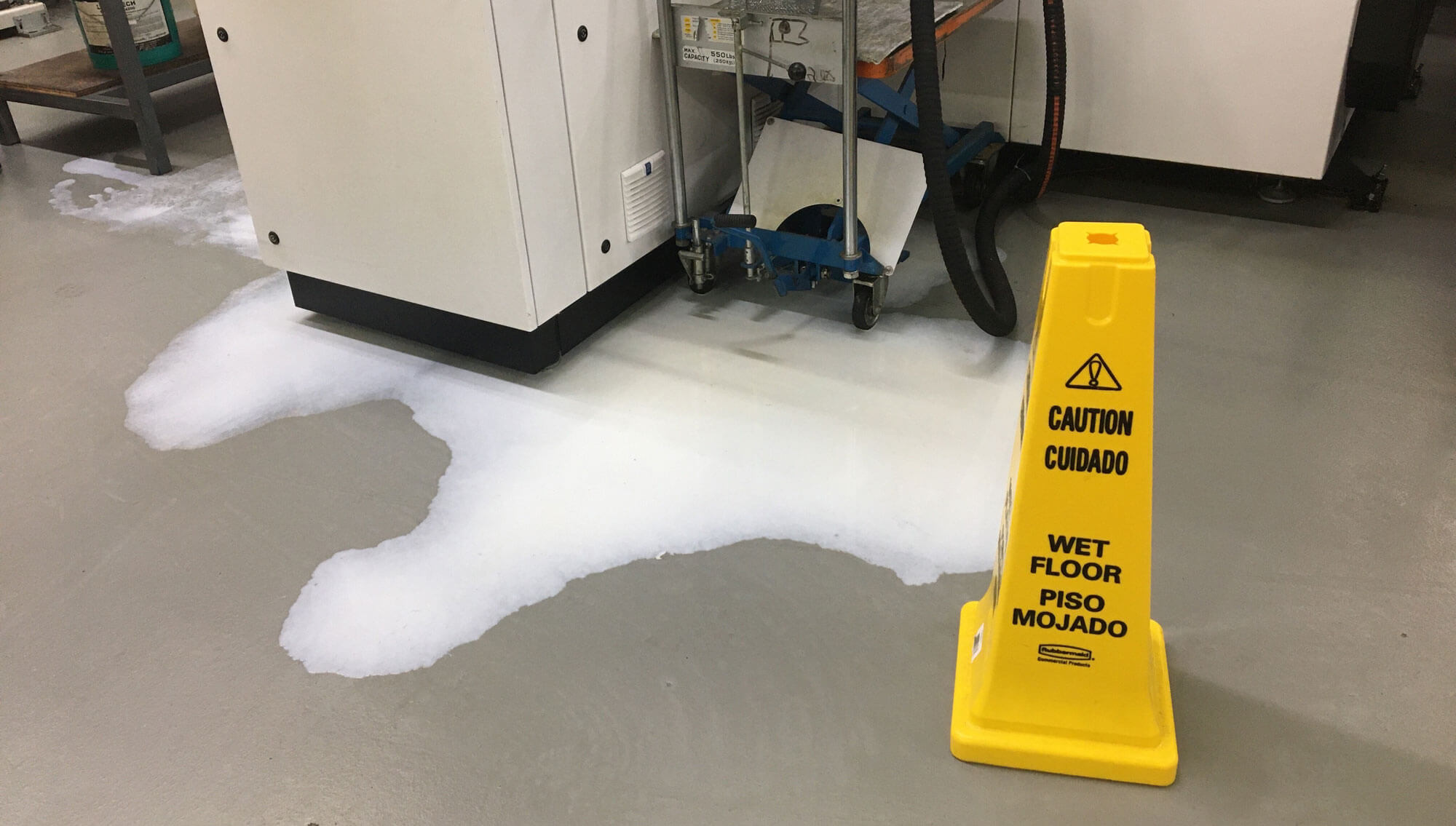

Recently, after everyone had clocked out for the day, aluminum chips clogged the drains on one of our CNC machines. This clog now trapped coolant inside the machining area of the CNC, causing coolant to slowly drain back to the sump. With the sump full of coolant, we were headed to what’s known as the flooded floor—a common occurrence in shops all around the world that can be avoided.

What Could Have Happened:

The coolant would have eventually overflowed—creating a large mess that would go unnoticed until the next morning. By that point, we would need to halt all production for several hours to clean up the mess with mops, forklifts and safety barriers.

What Really Happened:

The FullShop™ system sent out an automated message, warning us that the CNC machine had a high level of coolant. We entered the shop, investigated the machine and cleaned up the coolant with a rag, resolving the issue in five minutes.

Enabling True Lights-Out Operation

Thanks to this real-time capability, FullShop™ saved us several hours of downtime and hundreds of dollars in lost productivity. These email notifications are just one of the system’s many IoT-enabled features that give you the confidence everything is working as it should—even overnight.

To learn more about 168 Manufacturing’s FullShop™ system, please visit: www.168mfg.com/system.