Technology Blog

Coolant Concentration Control—Why Unique Ratios Matter

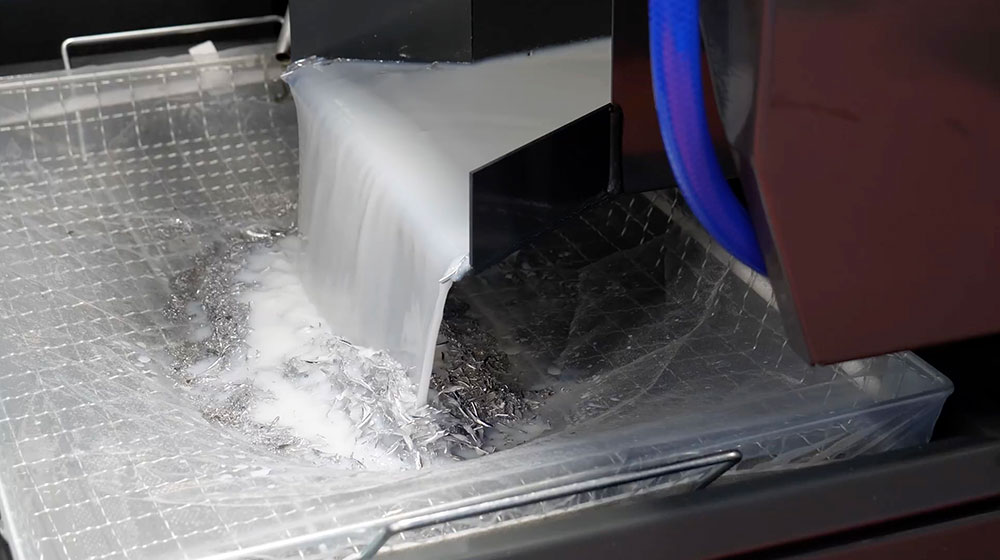

Many metalworking shops suffer from frequent coolant concentration issues because topping off is not individualized to each CNC machine and process. Instead, these shops employ a one-size-fits-all top-off strategy that causes some machines to run rich and others to run too lean. Over time, the lack of individualized, controlled coolant concentrations can lead to costly problems—ranging from tool wear and poor machine performance to wasted coolant and labor to manually fill sumps.

To address these coolant concentration issues, we developed the FullShop™Automated Coolant Management System. It automatically mixes and distributes coolant to as many as 120 CNC machines through a scalable system of remote valve manifolds. Importantly, the system provides individualized coolant top offs to every machine it serves, maintaining optimized coolant concentrations at the machine level. Contrast this approach to the chaotic coolant concentrations that result from the one-size-fits-all top-off strategy that most machine shops employ.

Customers input refractometer data into the FullShop™ Coolant Health App which trends and visualizes the sump concentration and prescribed dosing strategy. Customers use this correlated data in the app to make adjustments for optimal coolant dosing for each machine. The app also has the ability to send alerts and weekly reports to coolant related events—such as overdue refractometer readings or out-of-control concentrations.

Since coolant dosing is optimized per CNC, you won’t waste coolant running overly rich sumps or burn up tools due to lean conditions. This also leads to a more predictable plant floor and enables more lights-out production. Another immediate benefit of this system is the redistribution of labor. Instead of filling up coolant sumps, workers are available for higher-priority tasks that provide more immediate profitability.

FullShop™ systems are also modular and can manage the coolant requirements for up to 120 CNC machines (depending on the model) and provide a high degree of flexibility and scalability when setting up your shop floor.

Visit our website to learn more.