Technology Blog

Are Those Thousands of Minutes Invested in CNC Machine Coolant Top-Offs Free?

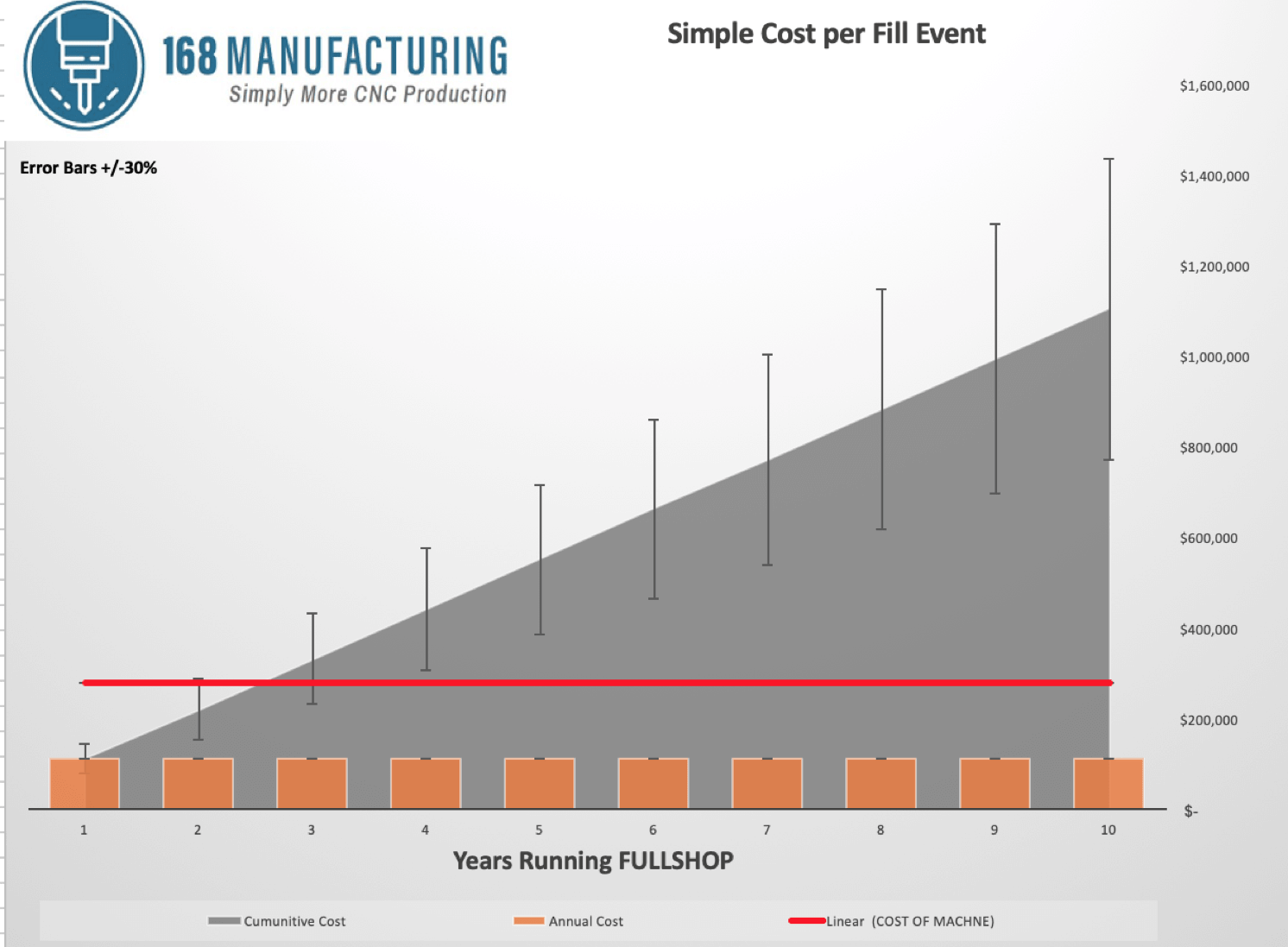

Continuing our series on how automatic coolant refill systems maximize your return on investment (ROI), we now turn to simple cost per fill events. They’re free, right?

The Bucks Add Up

The reality is, it costs you something each time someone has to monitor, mix and fill a CNC machine. And when something goes wrong, you have to pay someone to fix it. All these costs add up—especially if you have multiple CNC machines in your shop running multiple shifts.

Let’s break down a few scenarios using typical data.

An average CNC machine should get filled once per shift—sometimes more, sometimes less. The time it takes to do this typically ranges from 5 to 20 minutes, so let’s use 10 minutes at a cost of $0.50 per minute ($5.00).

Use Case #1—A shop that runs Monday to Friday (three shifts each) plus Saturday and Sunday (two shifts each), totaling 19 shifts per week:

- 24 CNC machines = 456 top-offs = $2,280 per week = 4,560 minutes invested weekly

- 36 CNC machines = 684 top-offs = $3,420 per week = 6,840 minutes invested weekly

- 72 CNC machines = 1,368 top-offs = $6,840 per week = 13,680 minutes invested weekly

Use Case #2—A shop that runs Monday to Friday (two shifts each), totaling 10 shifts per week:

- 24 CNC machines = 240 top-offs = $1,200 per week = 2,400 minutes invested weekly

- 36 CNC machines = 360 top-offs = $1,800 per week = 3,600 minutes invested weekly

- 72 CNC machines = 720 top-offs = $3,600 per week = 7,200 minutes invested weekly

Imagine redeploying 13,680 or 7,200 minutes of labor to more meaningful tasks? How would this affect your bottom line?

Automatic coolant refill machines like our FullShop™ Automated Coolant Delivery Systemautomatically replenish coolant before it runs low, eliminating the need to manually refill coolant and saving you money and time on each event. Our system even includes real-time Internet of Things (IoT) capabilities, such as email notifications, data reporting and analytics, which help you proactively address maintenance issues before they arise.

When all is said and done, you can make back your money on a FullShop™ machine after only three years in terms of simple cost per fill events alone, using the scenario above.

To learn more about this game-changing machine, check out our data sheet.