THE FULLSHOP™

AUTOMATED COOLANT

MANAGEMENT SYSTEM

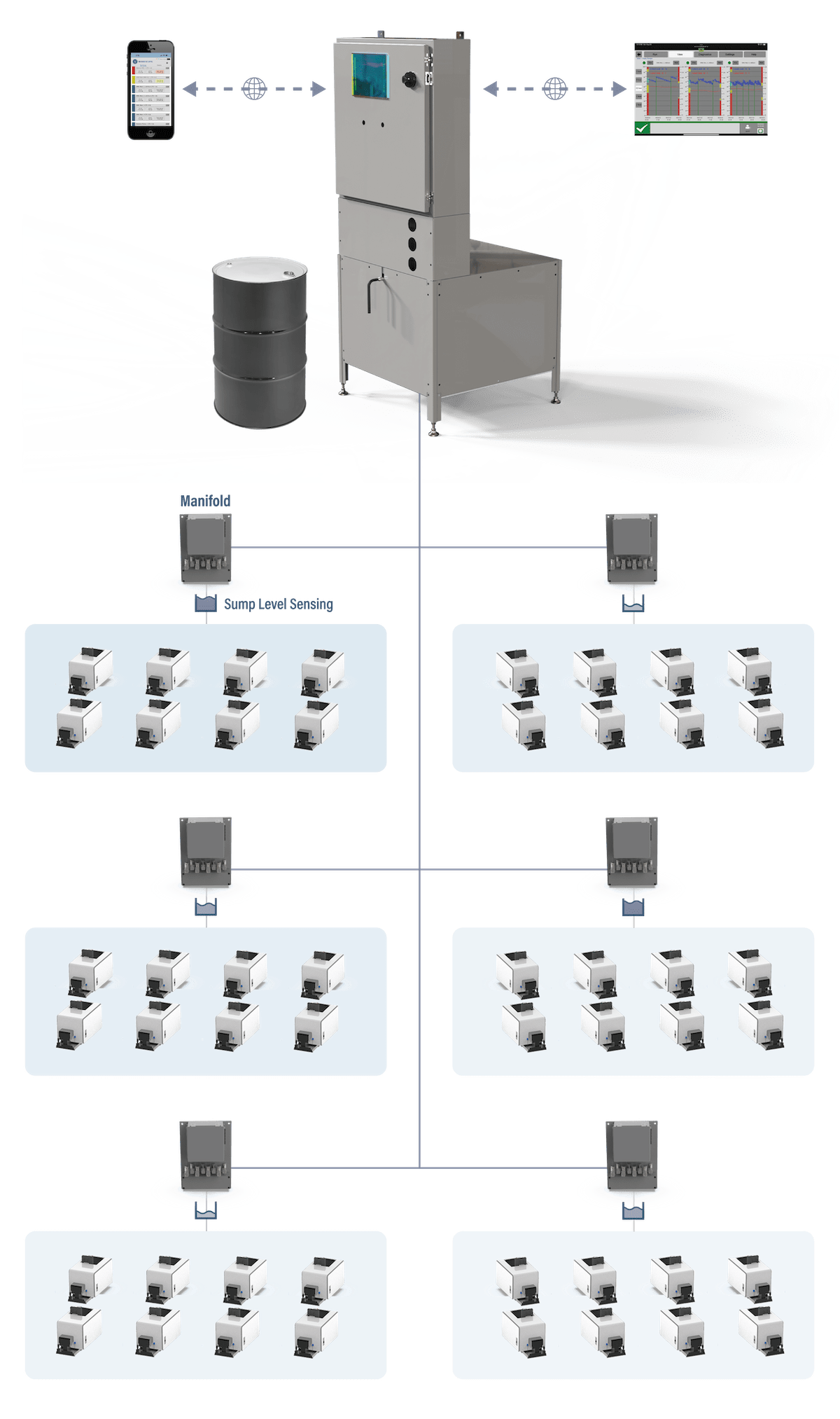

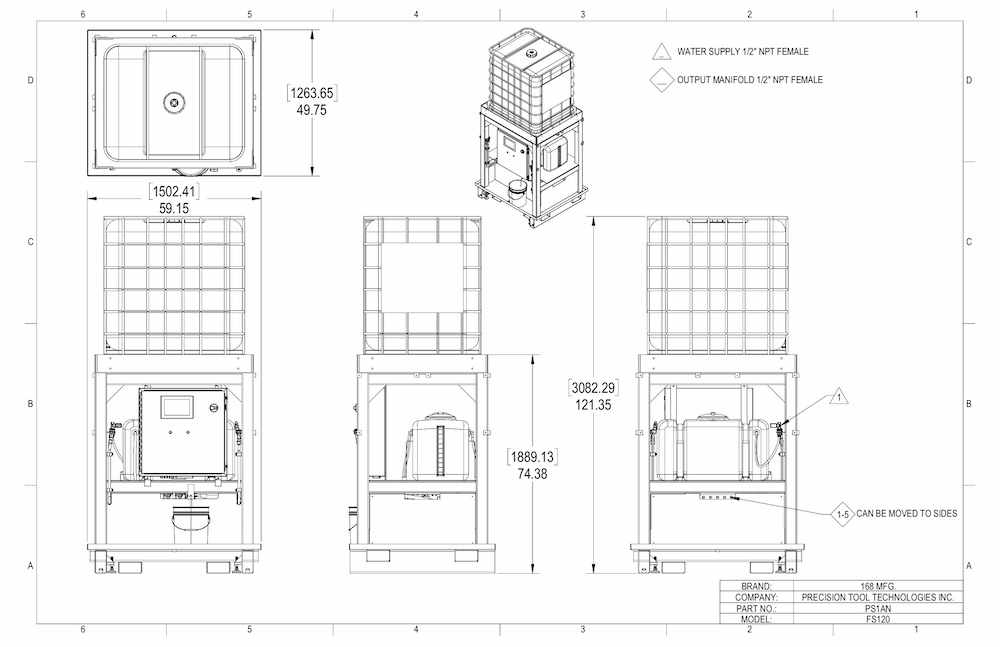

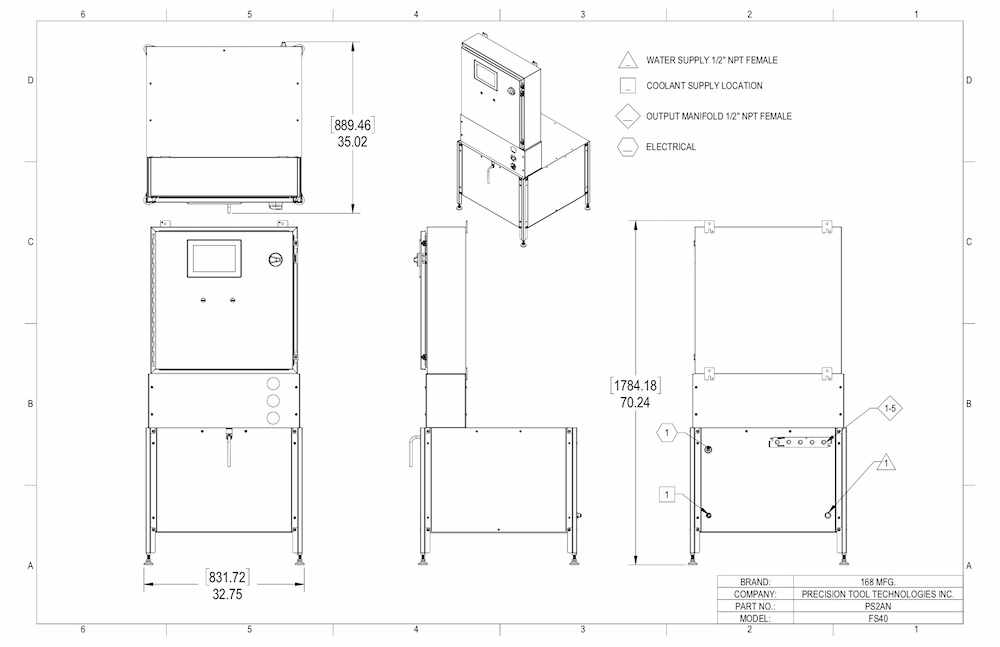

These easy-to-install turnkey systems consist of a centralized pumping station, controller, distribution manifolds and a small level sensor that drops into any machine tool sump. With its compact footprint and modular design, our FS120 model can automate shops with 15 to 120 CNC machines — delivering up to 5,760 gallons of coolant a day. You can also select our smaller FS40 model, which can automate shops with up to 40 CNC machines.

MAKE MORE WITH AUTOMATED COOLANT MANAGEMENT

Optimized | Simplified | Ruggedized

FullShop™

Coolant Management Solution

Scalable filling, mixing and control for up to 120 CNC

fluid control system for level and concentration control.

Link

control manifolds. Simplifies install.

for each CNC. (Individually controlled)

single Ethernet cable and fluid

can be distributed in series or parallel.

remote OEM tech support

Unit works with DI, RO, municipal and ground water.

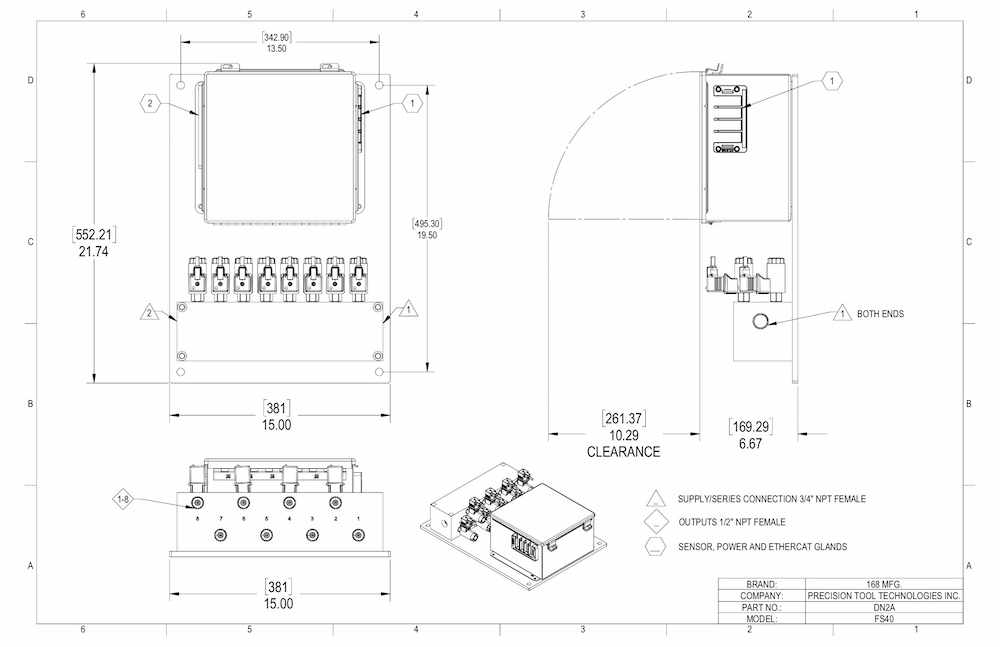

Remote Fluid Control Manifolds

Optimize each sump with user defined top-off ratios

Simple installation with reduced plumbing and cabling

FS40 systems support up to five eight-station manifolds.

FS120 systems support up to five 24-station manifolds.

real-time notification per CNC.

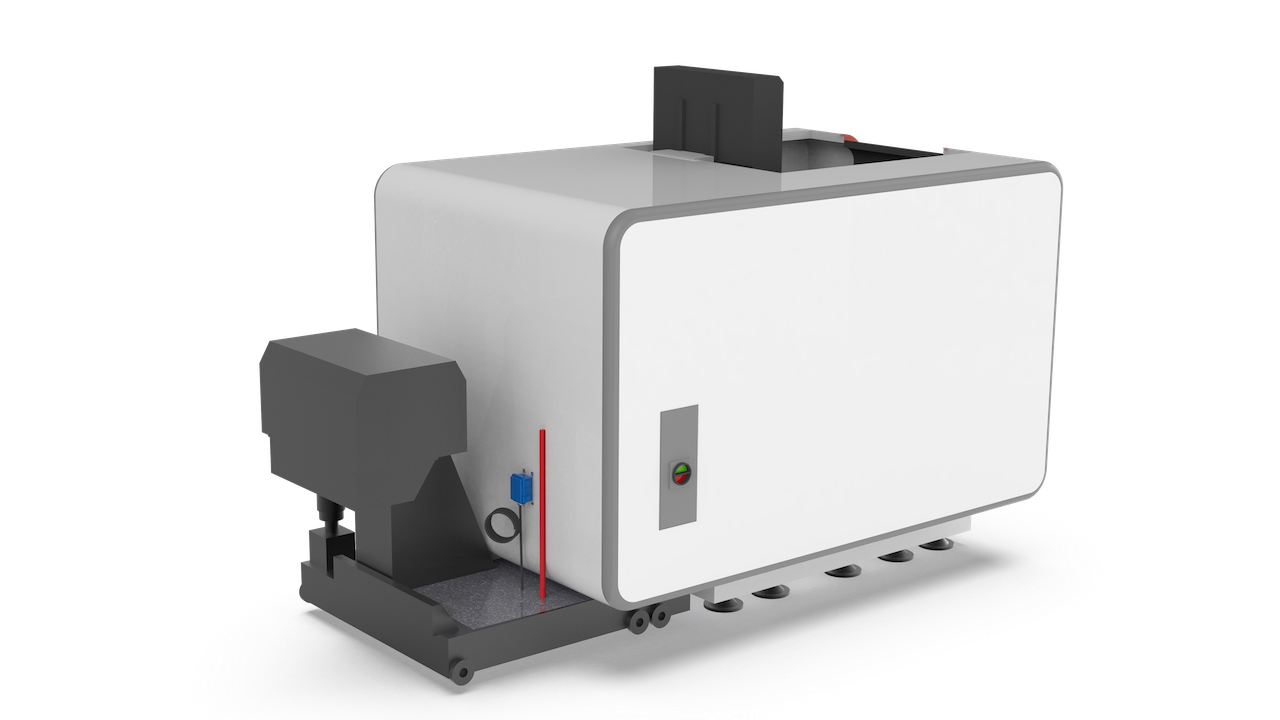

Robust and Universal For Any CNC

Level Sensing

Trouble free operation

Simple install, fits all machines.

Multiple redundancies for flood protection.

FULLSHOP ™ AUTOMATED COOLANT GALLERY

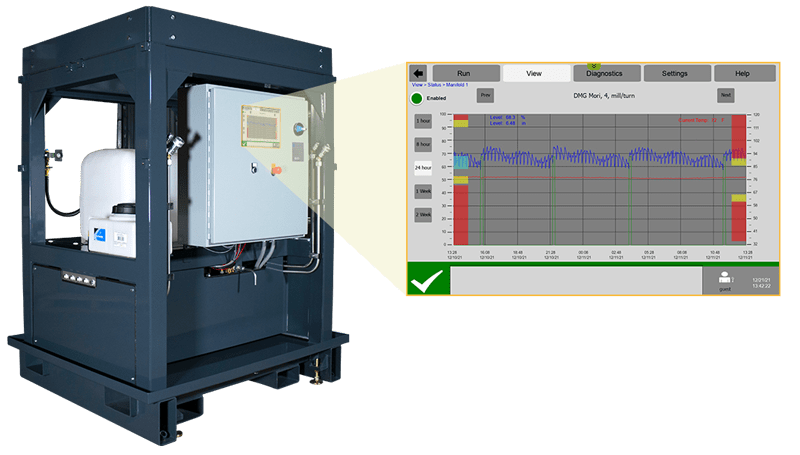

Optimized Coolant Starts with Great Machine Software

Using state-of-the-art software, FullShop™ automatically delivers properly mixed top-off coolant to CNC machines. Designed to optimize the coolant monitoring and management processes, its software offers machine sump level control, coolant recipe management and real-time IIoT capabilities like email alarms and notifications. The software can also run system diagnostics, provide real-time status updates — and much more.

Machine Application

- Level control

- Recipe management

- User management

- Email alarms and notifications

- Diagnostic capabilities

- Usage and fill event data

- Real-time status updates

- Displays historical trends

- Audit trail

- Remote operation

Videos

System Requirements

- 460VAC / 3-phase power connection.

- Plumbed water service to equipment.

- Optional Internet connection for teleservice and reporting functions.

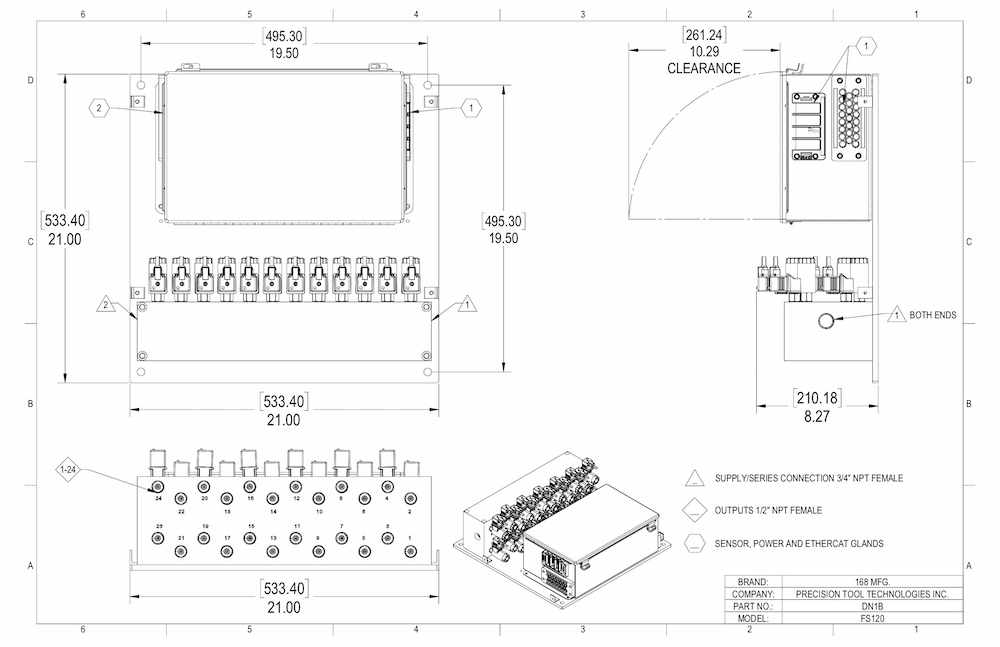

Dimension Drawings

Technical Specifications

| Model | FS120 | FS40 |

|---|---|---|

| System Services | ≤ 120 CNC | ≤ 40 CNC |

| Each Distribution Node Services | ≤ 24 CNC | ≤ 8 CNC |

| Max. Distribution Nodes | 5 | 5 |

| Concentrations, percent | 0.5 to 20 | 0.5 to 20 |

| Footprint, inches | 50 x 60 | 30 x 30 |

| Power requirement, VAC | 460 | 460 |

| Water | RO, DI, Municipal, Well* | RO, DI, Municipal, Well* |

| Remote Operation | Yes | Yes |

| Remote Teleservice | Yes | Yes |

| Tubing Run Length, feet | Up to 2,700 | Up to 2,700 |

| Sump Sensor | Level and Temp | Level |

| Inlet Water Sensor | Temp and Quality | Temp and Quality |

| Compatible with FullShop™ App | Yes | Yes |

| Screen Size, inches | 10.1TFT | 7.0TFT |

Start RFQ

Please use this form for quote requests, general inquiries or questions about our coolant automation technologies. We will review your request and a technical sales representative will be in touch shortly.

DOWNLOAD DN1B DIMENSIONS »

DOWNLOAD DN1B DIMENSIONS » DOWNLOAD DN2A DIMENSIONS »

DOWNLOAD DN2A DIMENSIONS » DOWNLOAD FS120 DIMENSIONS »

DOWNLOAD FS120 DIMENSIONS » DOWNLOAD FS40 DIMENSIONS »

DOWNLOAD FS40 DIMENSIONS »