Thoughts on CNC Coolant Refractometry With Automated Top-off Systems

From a cost, time and reliability standpoint, manually collected refract data entered in a mobile app, coupled with automatic dosing, is a real sweet spot.

Which Approach Works Best When Using An Automated Top-off System?

As automated coolant systems become more popular, new options are hitting the market. Some of the newer systems use inline refractometers to automate refract readings, which has traditionally been a manual measurement process. All these automated systems have different approaches to measuring and adjusting the coolant to ensure each CNC machine has the proper coolant concentration in the sump.

Yet despite the apparent benefits of automated readings, at 168 Manufacturing, we currently believe automating this quick and simple process isn't all it's cracked up to be. We believe taking manual readings is still the way to go for most customers.

Manual Versus Automated Refract Readings: Which Way is Truly Best?

Optimizing concentration in a CNC sump requires refractometer data. There is no way around it. This data is used by these automated solutions to assure optimal dosing ratios during the auto-fill process. Having the correct sump concentration will improve the quality of the machined parts and ensure optimal machine performance and tool life.

Did you know that only a few weekly readings are needed to stabilize sump concentrations when an auto-fill system doses an optimized top-off ratio? A simple mobile app makes using any handheld refractometer a snap and can drive the required accountability. However, some automatic coolant refill systems have automated this traditionally manual measurement process using built-in refractometer sensors. Despite the apparent benefits of this approach, we believe manual refractometer readings are still the way to go for most customers.

Here Are Some Reasons Why

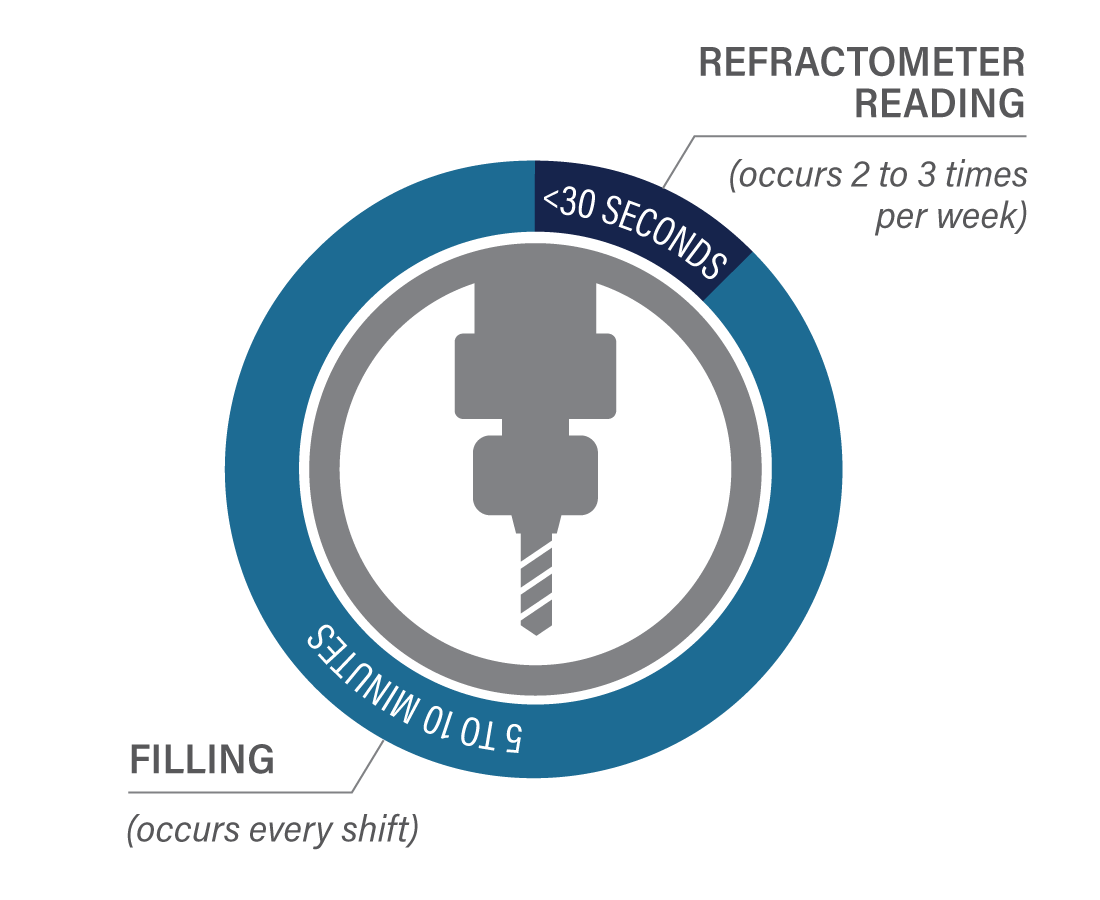

Negligible time savings. Automating this task — which takes less than 15 seconds using a handheld refractometer — doesn't really save much time and labor. Systems that can dose CNC machines individually only need a few data points per week to stabilize sump concentrations.

CNC sumps are no place for a refractometer. Our research and development (R&D), plus field experience, have taught us that CNC sumps are a challenging environment for refractometers to survive in. These sensors are easily fouled and can require frequent cleaning.

Integrating inline refractometers can be complex and expensive. A ruggedized, inline refractometer at each sump is an expensive proposition, and without centralized software, that data is on an island. Centralizing a single sensor requires complex plumbing. How strong of a value proposition is it really for this type of application?

A regular look at overall sump condition is a healthy practice. We encourage you to talk to your coolant professionals, as they universally agree that a simple, visual review of the sump is a huge value-add to any coolant program. This process can go a long way toward ensuring problems are identified.

Handheld refractometers and mobile apps are a simpler package. Integrating automated sensors drives cost and complexity in a way that is hardly justified — especially given how easy and convenient it is to use a modern mobile app alongside a handheld refractometer.

Coolant Filling — Where Does the Time Go

Without coolant automation, the care and feeding of your CNC sumps can be time consuming. Your operators may spend five to ten minutes per shift taking refractometer readings, filling buckets with coolant and lugging the buckets to the machine. In a shop running three shifts a day with only 20 machine tools, manual coolant operations would cost you hours of labor every day. Not surprisingly, taking the coolant readings is the least “expensive” part of this process, taking less than 30 seconds and only two or three times a week. For this reason, our FullShop™ system focuses automating the fill itself, not the refractometer readings.

Automated Coolant Delivery and Dosing Using Manual Coolant Measurements

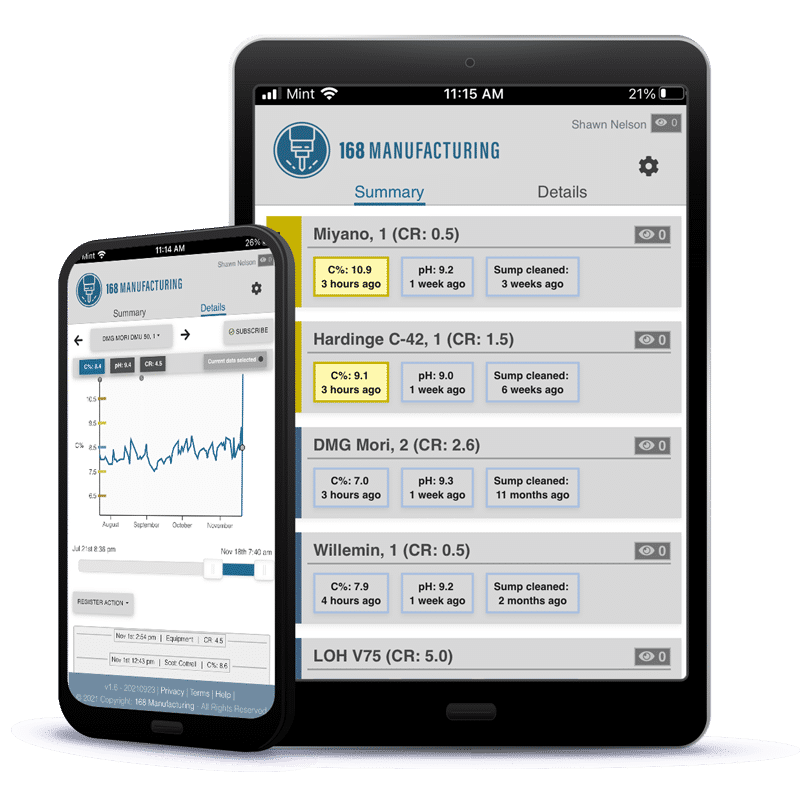

Our FullShop™ system will auto-fill all the CNC machines in your shops while dosing each CNC machine individually with a unique top-off ratio based on the trends and data submitted to the Coolant Health App.

For most machine shops, we currently believe the tried-and-true method of manual refractometer measurements, coupled with auto-fill and unique dosing per CNC machine, is the most beneficial solution from a time, cost and ROI perspective.

While we believe the time, cost and reliability implications do not justify replacing manual refractometry, we are able — upon demand — to incorporate automated sensing into our FullShop™ system if your use case demands it.

Questions? We're here to help.