Coolant Tending Simplified With Automated Coolant Management

168

FullShop™ GEN 3*

Affordable Coolant Automation

We’ve reengineered our FullShop™ solutions from the ground up, making them better than ever and much more affordable. FullShop™ Gen 3* leverages modern IoT technologies alongside a simpler fluid architecture to deliver better value, performance and simplicity. Tremendous focus has been put into reducing installation and startup efforts. When released, FullShop™ Gen 3* will be available through as subscription service for a compelling ROI out of the box.

Stay informed on our next generation of coolant automation systems by joining our mailing list or by following us on LinkedIn.

Automated Coolant Management

If you’re still dumping buckets of coolant into your CNC machines, there’s a better way.

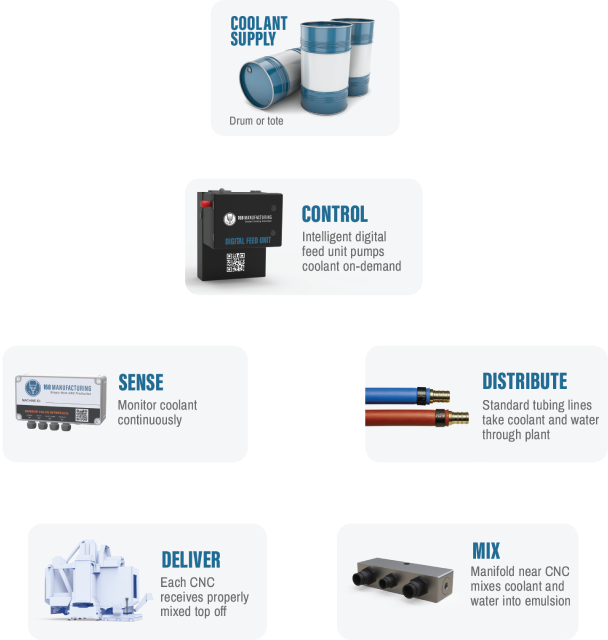

Built on years of experience from a real-world CNC shop, FullShop™ easy-to-install turnkey solutions consist of well-thought-out hardware, software and sensors. And with their compact footprint and modular design, they can automate shops of nearly any size.

Benefits

FullShop™ solutions deliver properly mixed coolant concentrations on a per-machine basis thanks to their advanced controls and modular distribution system. These solutions monitor coolant at the machine tool sump and automatically replenish the coolant before it runs low with the correct top-off ratios.

In addition to hitting your target concentrations, FullShop™ unlocks a range of benefits:

- Increase profitability. The FullShop™ system drives business profitability by helping you better utilize your capital.

- Maximize worker value. In this tight labor market, your skilled CNC machinists can focus on their craft without serving on the usual bucket brigade. Data shows that the first hour of every machine shop shift is not as productive as workers rush to fill machines with coolant.

- Improve throughput. The FullShop™ system eliminates low-coolant faults when machines operate unattended over nights and weekends. As a result, your spindles keep spinning.

- Ready for Industry 4.0. The FullShop™ system integrates advanced, Internet-enabled features to help you optimize your profits — including data reporting, remote operations and teleservice. We also built in email notifications, data reporting and analytics trending.

- Get up and running quickly. The FullShop™ system is a complete, pre-engineered solution with a short learning curve.

- Real return on investment. With a robust design intended for years of service, the FullShop™ system helps you produce year after year.

Let's Talk

Please use this form for quote requests, general inquiries or questions about our coolant automation technologies. We will review your request and a technical sales representative will be in touch shortly.